PLASTICS

MOLDING COMPANY

What we do

Engineering Design

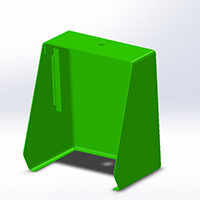

Prototyping

We have 3D modeling capabilities that allow us to turn the customer’s design into a mold that we can quickly produce prototype parts from. Design changes are easily and quickly accommodated with our in-house tooling capabilities.

Mold & Tooling Building

Our tooling team designs and fabricates tooling with the most advanced materials to provide reliable, lasting tooling. Molds can be made from materials such as Pine, Ceramic Fiberglass, Composites, and temperature controlled Aluminum.

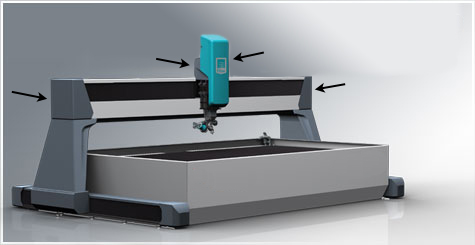

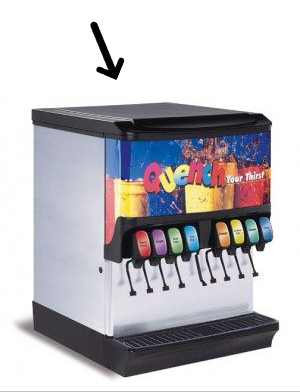

Fabricating

We offer a variety of materials and fabrication techniques to make custom products depending on the customer’s need. With multiple 3 and 5 axis CNC routers we can cut plastics with precision and efficiency. We have several line bend machines that allow us to make many different variations of POP displays and covers.

Vacuum / Thermoforming

Vacuum thermoformed parts are good replacement options for fabricated sheet metal components with complex shapes. We offer the highest level of technology to accomplish this for our customers. We have state of the art, modern vacuum forming equipment that allows us to be very efficient and precise in the production of molded parts.

Injection Molding

We offer custom injection molding with press sizes from 75 tons up to 720 tons. We specialize in custom niche projects, running volumes as low as 50 parts, and up to millions of parts per year. We also have a long standing relationship with a China tool maker that can offer inexpensive molds if your budget doesn’t allow stateside mold costs.

Sheet & Raw Stock Materials

There are millions of applications for plastic sheet, tube, & rod. We offer engineered/mechanical plastics, sheet, and sign & graphics plastics. We stock a variety of plastics including but not limited to: ABS, Acetal, Acrylic, Nylon, Foam Board, Kydex, PVC, PETG, Polycarbonate, Polyethylene, Polypropylene, Polystyrene. Profile shapes, rod, tube, sheet, Urethane, scratch resistant, corrugated and UV resistant.

Generating New Ideas. Solving Big Problems

Projects

Satisfied Clients

Ongoing Projects

Cups Of Coffee

Why we are different

Our Latest Work

“I’ve worked with Todd and TLD for almost 20 years on dozens of projects. The reason is Todd makes it happen. We’ve done thermoforming, injection molding, built Injection mold tooling (some big ones!) and numerous other projects. Todd has always leveled with me. He’s a stand-up guy, and been great to work with.”

His knowledge of material and design has served us well.